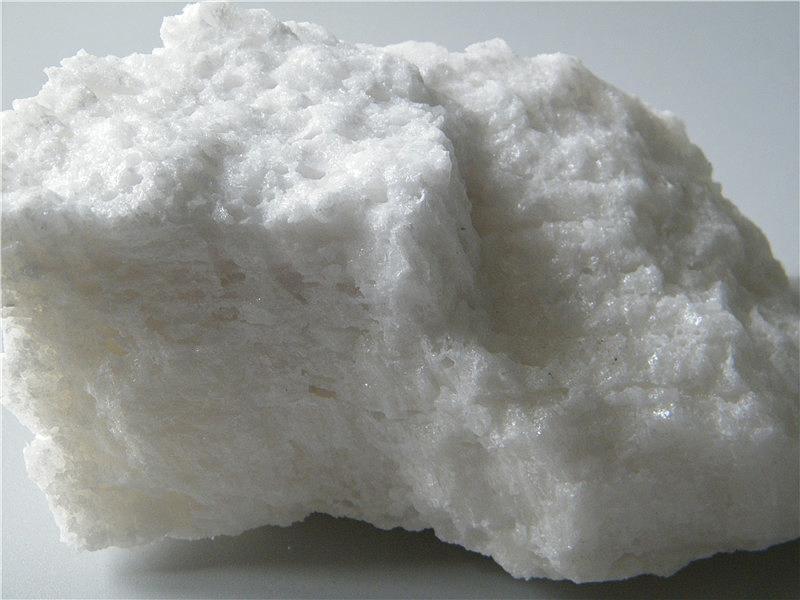

White corundum grinding wheel

White corundum grinding wheels are abrasive tools that are smelted in an electric arc furnace using industrial alumina powder as the main raw material. White corundum grinding wheels are made from industrial alumina powder as the main raw material and smelted in an electric arc furnace. The main mineral component a-ALO is greater than 98%. Its hardness is similar to brown corundum, but its toughness is lower. Its cutting performance is higher than brown corundum. White corundum grinding wheel is one of the most important abrasive tools in grinding processing. White corundum grinding wheel is a porous body made by adding a binder to the abrasive, compacting, drying and roasting. Due to different abrasives, binders and manufacturing processes, the characteristics of grinding wheels vary greatly, which has an important impact on the processing quality, productivity and economy of grinding. The characteristics of grinding wheels are mainly determined by factors such as abrasive, strength, bond, hardness, structure, shape and size. There are many types of grinding wheels. According to the abrasives used, they can be divided into ordinary abrasive (corundum, silicon carbide, etc.) grinding wheels. According to the shape, it can be divided into flat grinding wheel, bevel grinding wheel, cylindrical grinding wheel, cup-shaped grinding wheel, disc-shaped grinding wheel, bowl-shaped grinding wheel, concave grinding wheel, cone grinding wheel, etc.; according to the binder, it can be divided into ceramic grinding wheel, resin grinding wheel and rubber grinding wheel. , metal grinding wheels, etc. The characteristic parameters of the grinding wheel mainly include abrasive, particle size, hardness, bond, shape, size, etc. Since the grinding wheel usually works at high speed, a rotation test (to ensure that the grinding wheel will not break at the highest operating speed) and a static balance test (to prevent machine tool vibration during operation) should be performed before use. After a grinding wheel has been in operation for a period of time, it should be dressed to restore grinding performance and correct geometry.